You’re probably wondering how long it takes to 3D print because you have a very short deadline. Here’s our short answer to that:

On average, 3D printing an object can take anywhere from 30 minutes up to 12 hours to print. Sometimes, it can even take several days depending on how large and detailed your 3D model is.

The time it takes to 3D print a part depends on a number of factors. Size, height, complexity, and printing technology are a few examples. Read on to discover more about 3D printing speed.

Why Does 3D Printing Take So Long?

It first depends on the 3D model you want to print out.

3D printing larger, more intricate designs takes longer than printing smaller, easier designs. It would take longer to print 3D models with higher quality.

As you can see, there are a lot of factors that can affect how long something takes to print in 3D.

The length of time required to 3D print something depends on a number of variables, including the material being used, the size of your 3D model, and any post-processing you wish to do.

To help you better understand how long it actually takes to 3D print an object, we’re going to break down each factor in this article.

Factors That Affect the Time It Takes to 3D Print An Object

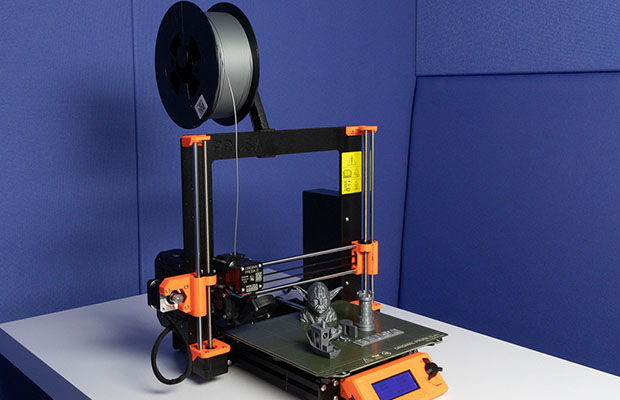

Type of 3D Printer

There are faster and slower 3D printing technologies. The rule of thumb is that faster printers cost more, so many of the fastest models are out of reach for the majority of consumers.

Type of Materials

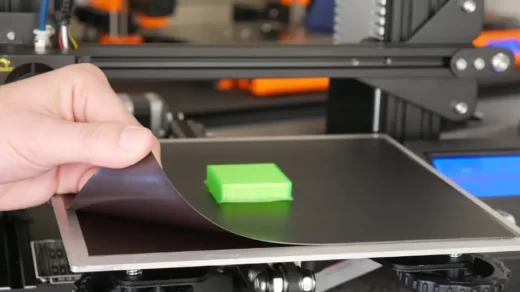

Some 3D printing materials are simpler to work with than others. In comparison to materials that are simple to process, harder materials have a tendency to slow down printing speed. As well as requiring various times to adhere and set, various materials also require various extrusion and bed temperatures. The speed of 3D printing is affected by all of these variables. Read More: How To Clean A 3D Printing Bed?

Size

When printing, the issue of size must be taken into account. The more layers a part needs, the longer it will take to print because the print head needs to make more passes.

The footprint (X, Y axis) of the part, along with its volume, is important. Larger footprints take longer to print because the print head needs to travel farther from its starting position.

Read More: How To Reduce Cost Of 3D Printing?

Amount

The number of parts being produced also affects how long it takes to finish a 3D printing job. Since you don’t have to set up the 3D printer tooling and materials for each part after the first, printing multiple copies of an object typically cuts down on print time. For more intricate parts with short layers, the decrease in print time is less pronounced because the printing procedure itself still takes a while.

Height

Height also matters, in addition to the part’s size. Taller parts require more passes than shorter ones during the layer-by-layer construction of the printed parts, which lengthens the printing process. Because of this, even though the volume of the parts is similar, printing a part that is 4x4x4 will take less time than one that is 3x3x7.

Type of Printing

The precise type of 3D printing employed also affects how long it takes, with some processes being slower than others. Painting with a brush or rolling paint are the two categories that best describe 3D printing processes. The material is extruded from a single point using the paintbrush technique as it moves across the build tray. The paint roller method evenly moves back and forth across the entire build tray while extruding material from various locations on the print head. Printing with a paintbrush takes longer than printing with a paint roller.

Geometry / Complexity

The length of time it takes to print an object also depends on how intricate the geometry of a part is. The geometry of the part will take longer to print the more complicated it is.

For instance, the print head will need to create the boundaries for these parts before filling each one in if a part has numerous complex layers. The kind of 3D printing technology you use can also affect how long the build takes because some technologies can deposit complex geometries faster than others.

Infill

The internal framework of a 3D part is called the infill. The complexity of the infill pattern will have an impact on the print speed, with more complex patterns taking longer to produce. Though a higher density infill lengthens print times while also enhancing the strength of the finished part, density has the greatest impact on print speed from infill.

Quality / Layer Height

The layer height is directly proportional to the quality of a printed part. Typically, each layer is between 0.1 and 0.5 millimeters thick (100 and 500 microns), with thinner layers offering a better finish and higher quality. But it also takes more time to make these fine, high-quality layers.

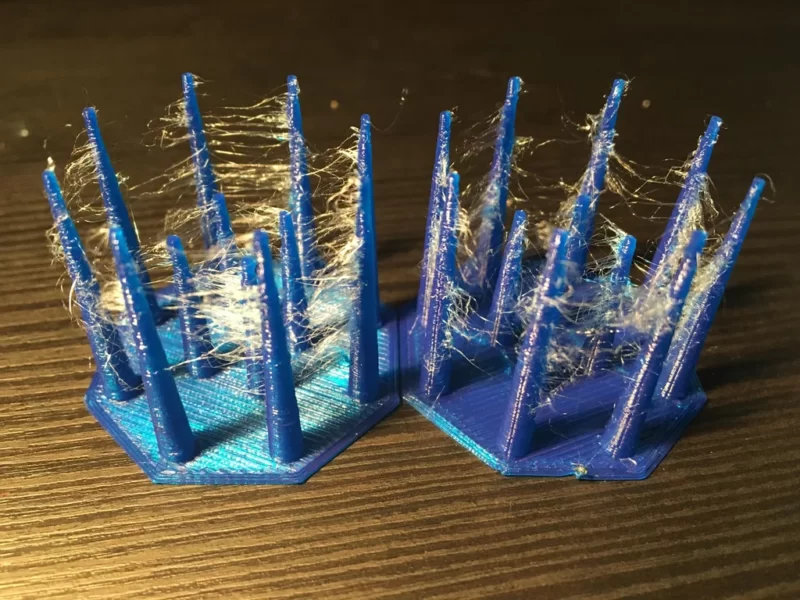

Post-processing

Post processing is the deciding element that can slow down printing. In order to do this, printed parts must be cleaned, rinsed, and dried. Depending on the size and geometry of the 3D printed parts, each technology has different post processing requirements. While cleaning smaller, simpler parts may only take a few minutes, cleaning larger, more complicated ones may require several hours of post-processing.

Read More:

How to Speed Up Your 3D Printing Process?

Keep in mind that there are tradeoffs when trying to speed up your 3D printing

- Achieve optimum speed by tuning your 3D printer. Be careful with this because you might lose quality and increase your chance of failing.

- your 3D model at a smaller scale. If size don’t really matter then 3D printing it at a smaller scale would decrease the time it takes to print

- At the same time, print them all. You might be able to get away with 3D printing your parts next to each other if your printer is big enough.

- To save time, work with a reputable 3D printing service. 3D printing companies like us can do 1-2 day turnaround depending on your project. Our large-scale 3D printers can print numerous parts simultaneously.

Read More: How Much Electricity Does a 3D Printer Use?

Frequently Asked Questions

We have answered some of the frequently asked questions below for your convenience.

How Long Does It Take to 3D Print a Cube?

In total, it takes 14 hours and 5 minutes to 3D print a prosthetic hand.

How Long Does It Take to 3D Print a Cup?

In about 3-5 hours of print time, you can have your very own crushed coffee cup. Maybe your 3D-printed cup will look as good as it tastes.

How Long Does It Take to 3D Print a Car?

That’s 48 hours of printing the car’s body plus its components, not factoring in the post-processing work that would need to go into the finished car.

How Long Does It Take to 3D Print a Miniature?

28mm miniatures can be 3D printed in as little as 3 to 4 hours. For large miniatures, it can take up to 12 hours and occasionally even longer. The degree of accuracy you desire from your 3D printer will also play a role. A slower 3D printing process would result from more accurate prints.

How Long Does It Take to 3D Print a Phone Case?

Contrary to popular belief, it is not cost-effective to 3D print a phone case because they can take some time. Depending on the complexity of your design and your preferred 3D printing technology, a phone case may take 3 to 8 hours to 3D print. This will affect your pricing if you intend to sell 3D printed phone cases.

In Summary

3D printing a part can take anywhere from 30 minutes to 7 days or more. How long it takes to 3D print a part is determined by a number of factors.

If you’re only counting the time from loading it in a machine, it can take between 30 mins up to 12 hours or even days to complete. And 3D printing would take even longer if you factored in the extra time needed to make your creation functional or aesthetically pleasing.

Check out our 3D printing service to see if we’re a good fit for your 3D printing needs if you ever need a 1-2 Day turnaround.