When 3D printing resin, it is important to cure the 3D object so that it is completely dry and hardened. The curing process will make your resin prints stronger, harder, and less prone to breakage. Resin 3D prints typically take one to five minutes to fully cure under high UV light. The time required for resin 3D printing to cure depends on several factors. These factors include the size of the 3D model, the choice of resin, the curing method, and even the color of the resin. In this article, we will discuss the average cure time for 3D resin printing.

Table of Contents

Average Curing Times For a 3D Resin Print

The curing time of 3D resin printing is not absolute. Several factors determine how long it takes them to fully heal. Ultimately, the duration will depend on the type of resin you use, the size of the model being printed, and the curing method.

For example, a certain type of resin will cure within 15 minutes using a UV curing station. The same material may take several hours to cure in sunlight. There are also high-end cleaning and curing machines that can cure 3D objects faster than UV stations. The settings of these machines also affect the duration and efficiency of the process.

But again, your print size must also be taken into account.

Below are guidelines for several different model sizes using various curing methods. These are just guidelines and vary depending on the type of resin used and the exact intensity of the UV light.

- Elegoo Mercury

Cure time for standard 26mm miniatures – 2 minutes

Cure time for larger 100mm prints – 7-11 minutes

- Anycubic Wash & Cure

Cure time for standard 26mm miniatures – 3 minutes

Cure time for larger 100mm prints – 8-12 minutes

- UV Nail Lamp

Cure time for standard 26mm miniatures – 2 minutes per side

Cure time for larger 100mm prints – 6-8 minutes per side

- Sunlight

Cure time for standard 26mm miniature parts – 2-3 hours

Cure time for larger 100mm prints – up to 10 hours

Factors Affect Resin Curing Times

Different factors have different effects on the curing time of 3D resin printing. These include the surface area, shape or geometry of the print, UV intensity, temperature level, and the color of the resin.

- Opaque or transparent resin

Opaque resin materials, such as gray and black, take more time to cure than clear or transparent materials. This is because UV light can easily penetrate transparent materials. Because colored resins are more difficult to penetrate, they take longer to cure.

- Surface area and shape factor

The larger the surface area of a 3D resin print, the longer it takes to cure. As a result, tiny or small objects are expected to cure within minutes, as the UV wavelengths can quickly cover the entire surface.

At the same time, 3D parts with complex geometries or form factors also have longer curing times. UV chambers with rotating plates are recommended for this type of 3D resin printing because they cure complex shapes more uniformly and faster.

- Low or high UV wavelengths

Lower UV wavelengths take more time to cure the resin than higher UV wavelengths. An example of low UV is UV from sunlight, while high UV includes UV from UV curing stations. However, some UV curing stations have small lamps, while some have larger lamps that consume more power but cure faster.

This means that if you use direct sunlight to cure the resin, you can expect a longer post-cure process. In addition, the sun’s UV rays are affected by changing weather conditions, so UV intensity is difficult to determine and unstable.

- Temperature

Temperature also affects cure time. Post-cure is faster at elevated temperatures because it allows the resin-polymer network to crosslink. Therefore, as the temperature increases, the curing time also decreases.

There are bulbs in the UV chamber of the curing machine or curing station that provide heat to make the curing process faster.

How to Know When a 3D Resin Print Is Completely Cured

Knowing when 3D resin printing is fully cured is a great learning skill. It’s hard, but you can actually over cure a resin print, which will lead to brittleness. If a UV curing machine or strong UV exposure is used for too long, the surface of the model may become brittle and cause the surface to look a little rough.

Usually, when the surface starts to look silky or matte, that’s when your model is fully cured. If your model looks shiny or damp, it is not fully cured. If you over-treat, the model will start to become patchy and brittle.

The visual appearance depends on the type of resin you use, so your ability to find cured models may vary by material. But you can almost always use a general rule of thumb that your model should look almost flawless when cured.

Do Resin 3D Prints Cure Faster Underwater?

Resin 3D printing cures faster and more uniformly when cured underwater. Water scatters UV light, allowing it to reach objects from multiple directions at the same time. Since the bottom doesn’t see UV light, it still needs to be turned periodically.

When you cure resin 3D prints in sunlight, sharp lines form at the transition of sunlight and shadow. This means that only the side facing the sun is well treated and everything else has little or no.

You can also fix this by placing a turntable under the object. However, if you have a turntable, you can also get a UV light directly to optimize the process even more.

But even with UV lamps, underwater curing is still faster and more uniform.

Why Are Resin 3D Prints Sticky After Curing?

Sticky surfaces on resin 3D printing are caused by liquid resin residue. If the contaminated isopropyl alcohol used for cleaning contains too much liquid resin, it can also leave sticky areas.

Sticky spots on the surface of 3D prints usually indicate that the isopropyl alcohol* used to clean the object contains too much liquid resin.

You can dissolve liquid resin in isopropyl alcohol with UV light. You can achieve this in two ways:

- Let the isopropyl alcohol evaporate in the sun. Resin remains and cures.

- You put the isopropyl alcohol resin mixture in a clear bottle and leave it in the sun for a few days. The dissolved resin residue will harden and fall to the bottom of the bottle. The clear isopropanol can then be filtered off.

How to Avoid Sticky Resin 3D Prints?

The best way to avoid resin 3D printing stickiness is to use a two-step cleaning process. First, most resin residues are rinsed off with used isopropyl alcohol. The final residue is then removed using pure isopropanol.

So in principle, you have two different washes. On the first wash, you always use isopropyl alcohol that is already regularly used for cleaning.

The mixture of isopropyl alcohol and resin has enough resin to leave a residue, but not so much that you can still use it to wash off the rough residue. In the second step, pure isopropanol is used to remove the last residue from the first wash.

If the isopropyl resin mixture becomes increasingly milky and absorbs too much resin, it can be cleaned with UV light as described above. Clean isopropyl alcohol can then be used again.

How to Cure a Resin 3D Print

Resins cure when exposed to UV light, but there are various ways to expose 3D printing to UV light. If you want to cure your model in the fastest time, you should choose a professional curing machine or curing room.

If you don’t want to spend too much on a purpose-built machine, you can opt for UV nail lamps or even use natural sunlight. Lots of choices.

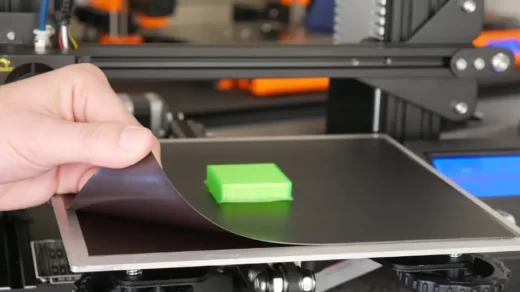

- Professional curing machine

Using a professional curing machine like the Elegoo Mercury is one of the most efficient ways to cure resin for 3D printing. These machines tend to encapsulate your print in a container and then evenly illuminate it under UV light around 405nm.

This enables your model to cure uniformly all-around at the same time. This will give you the most uniform surface possible, reducing the risk of over-curing certain points of the model.

- UV Nail Lamp

UV nail lamps are one of the most common methods of curing resin prints. This is what I used for years before investing in a curing machine!

These UV nail lamps are relatively inexpensive, especially compared to dedicated curing machines. They provide an economical and powerful UV light for curing resin models with ease.

The main disadvantage of using UV nail lamps is that it is difficult to get an even treatment on your model. You have to manually flip the model and drop it down to fix each side. This can be solved by creating a very simple DIY curing area.

You can surround your nail light with a cardboard box and make a closed reflective box out of reflective material like aluminum foil. This will make the UV light reflect more evenly around the print.

- Sunlight

If you don’t like buying any curing equipment, you can always take advantage of natural sunlight! Any skin care professional will tell you that sunlight contains natural UV rays, which are the main cause of skin damage. However, a positive effect of the sun’s UV rays is that these UV rays are strong enough to cure your 3D photos!

The sun’s UV rays may be strong, but they are nowhere near as strong as UV lamps. This means that sunlight will cure your resin print. It will take longer to do so!

Using UV light can heal your model in 2-5 minutes, while strong sunlight will take several hours. When printing with sunlight-curing 3D resin, you should immerse it in water and let it sit for several hours.

This curing method is not recommended as your UV light source should be as consistent as possible. The brightness of the UV light changes as the clouds pass, which means you can use sunlight to get a very uneven curing effect on your model.

After successfully repairing the 3D print, you can proceed to prepare and paint the model. Read our full guide on how to smooth 3D printing so it’s ready to draw.

Read More: How to Print on Metal?

Conclusion

It doesn’t take long to cure 3D resin printing. Generally, you only need to wait a few minutes for your print to be fully cured. But the exact number of minutes depends on factors such as the size and shape of the print, resin color, curing method, temperature, and other curing machine settings.

It is important to estimate the curing time to ensure that your project does not over cure and become brittle. Meanwhile, if it’s not fully cured, you can put it back in the curing machine for a little longer.

Related: Is 3D Printing An Expensive Hobby?