It’s important to consider all 3D printing costs when determining whether this is the right hobby for you.

How much electricity does a 3D printer use? The typical 3D printer consumes 70 watts of power with a heated bed of 60 degrees Celsius and a hotend of 205 degrees Celsius. This would consume 0.7kWh, or roughly 9 cents, for a 10-hour print.

The size of your printer and the temperature of the heated bed and nozzle are the two main factors that affect how much electricity it uses.

It needs to be as economical as possible. In this post, I’ll discuss how much power these 3D printers are consuming and how to control it.

Table of Contents

How to Calculate Your 3D Printer Power Consumption?

We have just seen the maximum price you can pay for 1 hour of printing on an Epsilon W50…but let’s see what else affects the consumption of a 3D printer:

- The printer model: There are other 3D printers that consume much more than those of BCN3D, reaching 1700W, so having a machine with low energy efficiency could double the electricity costs, at around 0.4 € per hour.

- The filament: Each substance must be melted at a different temperature; for instance, PLA melts at 200°C while ABS melts at 240°C. Using PLA instead of ABS when printing will therefore use less energy.

- Print speed: While printing more quickly will significantly lower the part’s overall energy cost, it will result in higher hourly consumption because printheads need more power to operate more quickly.

Factors That Affect 3D Printer’s Energy Consumption

Printer Size

The size of the printer itself has no effect on how much energy is used, but extra build volume does have an effect on how much energy is used during the printing process.

If a larger 3D printer is used to its full potential, the stepper motors will need to have more power to move the print across a larger build volume.

To heat a large surface area evenly and uniformly, a large bed needs more power (more on that below). The maximum wattage of larger 3D printers is typically higher due to these factors.

In contrast, a smaller printer with a smaller build volume will use less energy to heat up to the proper printing temperature and won’t require as much power from the stepper motors to finish a print.

Heated Bed

One of the 3D printing process’s most energy-consuming steps is heating the bed to an appropriate temperature, which is right up there with getting the hotend to a print-ready temperature.

The highest energy consumption of any stage of the printing process can be seen when a printer’s build plate is being brought up to temperature.

The energy needed to maintain the printer’s temperature after it reaches the desired level can vary depending on the surrounding temperature. To maintain, for instance, a 60°C bed temperature, a printer in a frigid room in the dead of winter needs significantly more power than on a warm summer day when the temperature is 30°C.

Hotend/Print Temperature

As mentioned above, the hotend, which is responsible for melting filament so that it can be deposited by the nozzle, is arguably the most crucial part of the 3D printing process.

A large portion of a 3D printer’s energy budget goes toward heating the hotend to melt filament. The majority of this occurs as the printer warms up to the proper printing temperature, then decreases to smaller spikes to keep the printer at that temperature.

Depending on the type of filament being used (PLA, ABS, PETG, or a high-temperature filament like Nylon), different temperatures will be needed. As a result, the power consumption may vary slightly.

Similar to how the heated bed is impacted by ambient temperature, the hotend’s heating element will have to work harder and take longer to reach a printing temperature in a colder environment.

Mainboard, Fans, Stepper Motors, and Display

When in use, the mainboard, fans, display, and stepper motor on a 3D printer each consume about 30 to 60 Watts.

These figures are modest compared to the heated and hotend, which can use up to 300 Watts to heat up, but they do contribute to the total power usage.

Print Time

Undoubtedly, a printer uses more energy the longer it operates. Print speed, print size, layer height, support structures, and infill density all play a part in determining print times, though they are outside the purview of this article.

Related Reading: How Long Does It Take to 3D Print?

Are 3D Printers Energy Efficient?

The answer is yes, 3D printers are energy-efficient. 50 to 150 Watts don’t mean much on their own, but when we compare them to typical home appliances, we can better understand how surprisingly little energy 3D printing uses.

A typical, consumer-grade 3D printer is covered by this, it should be emphasized once more.

We can infer from these wattages for the most popular home appliances that a 3D printer uses as much electricity as a video game console and a high-end TV.

How to Reduce the Power Consumption of Your 3D Printer?

Even though typical 3D printers don’t use a lot of energy, it can still be a good idea to minimize power usage. Additionally lowering electricity costs, this also has ancillary advantages like a shorter warm-up period. Allow me to explain.

The majority of power consumption reduction techniques focus on maintaining as much heat in the 3D printer (components) as possible. Since less heat is escaping, more energy can be used to raise the temperature. Because of this, components with good insulation are able to reach higher temperatures more quickly.

You can increase the effectiveness of your 3D printer using these techniques, which are the most popular ones.

Adding An Enclosure to Your 3D Printer

3D printer enclosures reduce energy usage by trapping heat inside, but they also provide additional benefits. For instance, the heated chamber they produce prevents warping of filaments (useful for ABS filament, for example), keeps potentially harmful 3D printing fumes inside, and lowers your 3D printer’s noise levels.

Construction of enclosures is not too difficult. Many tutorials can be found online that explain how to build an enclosure using IKEA furniture or straightforward wooden frames. As an alternative, you can simply order an aftermarket enclosure for your particular printer online.

Even better would be to purchase a fully enclosed 3D printer from the beginning, but these are more expensive than the typical open-frame 3D printer with the same build volume. The other advantages of the enclosure may offset this price difference, even though the decrease in power consumption won’t.

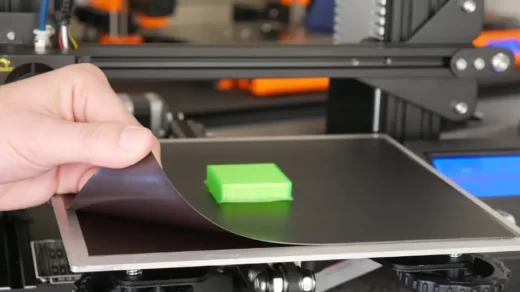

Insulating the Heated Bed

As you are now aware, the heated print bed of a 3D printer uses the majority of the printer’s power. Its large surface area makes it possible for a lot of heat to escape into the surrounding air. Fans for print cooling that continuously blow air over the surface are also ineffective.

A heated bed can be made to use less energy by having an insulation layer placed on the underside of the bed. A self-adhesive aluminum insulation mat or a cork sheet are both suitable options. The highest temperatures that heated beds can reach can be handled by both materials.

The bed will heat up considerably more quickly than it did previously afterward. The power needed to heat the bed is much greater because less energy is escaping to the surroundings. As they are frequently underpowered, beds powered by DC current (from the 3D printer power supply) can benefit the most from this.

Insulating the Hot End

The task of maintaining the proper temperature is equally challenging for hot end heating elements. Despite having a small surface area, they must constantly pump energy into filament and deal with cool air from print cooling fans removing heat.

The most effective way to lower a hot end’s energy consumption is to add insulation. This is something that a number of off-the-shelf products can do. The most common ones can be found as silicone nozzle covers or silicone socks.

Reducing Print Time

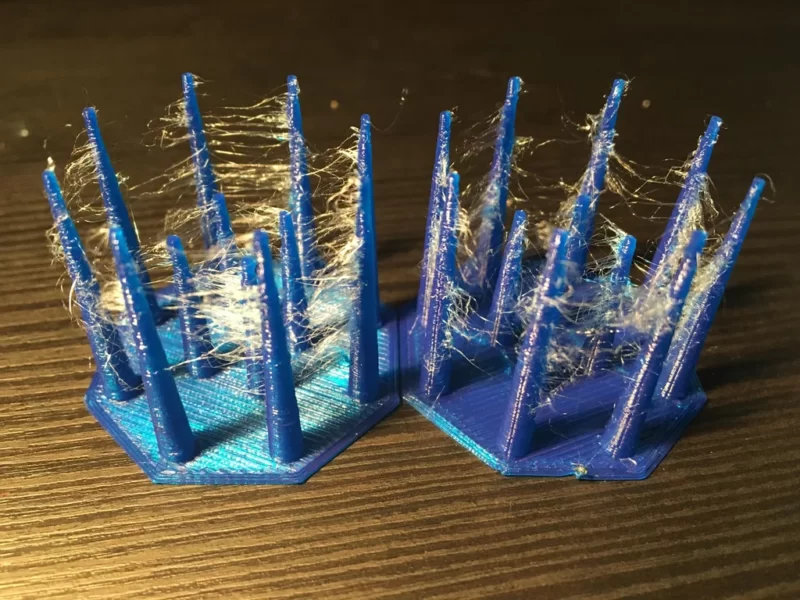

Simply cutting down on the time it takes to complete a 3D print is another method for saving energy on 3D printers. To achieve this, you can print with thicker layers, print at a faster rate, use faster infill patterns, or reduce infill.

One infill pattern that is both strong and difficult to 3D print is the hexagonal/honeycomb pattern. It is frequently preferable to choose something simpler and faster to print unless you specifically need its strength or aesthetics.

Setting these up requires striking the right balance because these measures do come with trade-offs (lower print quality, less strength in 3D prints, etc.). A CoreXY 3D printer is a fantastic choice if you’re looking for a printer that can produce prints quickly and with excellent quality.

Related Reading: How To Reduce Cost Of 3D Printing?

FAQs

Do 3D Printers Take a Lot of Electricity?

Ordinary 3D printers use only 50 to 150 Watts of electricity on average while printing.

How Much Does 3d Printing Cost?

3D printing can cost anywhere from $3 up to thousands of dollars. Without a 3D model, it can be challenging to determine the exact cost of a 3D print.

How Much Power Does a 3d Printer Use Per Hour?

The power can range anywhere between 43 and 182.4 watts.

Is It OK to Run a 3D Printer for 24 Hours?

3D printers can run 24/7 successfully as shown by many print farms around the world. Continuously operating printers occasionally experience failures, but generally speaking, they can operate simultaneously for several hours without experiencing any problems. Some large 3D prints take several days to complete.

Final Words

In conclusion, your 3D printer power consumption is a cost to be taken into account, but it’s not so high as to be an impediment to the use of this technology.

There are several approaches you can take to figure out how much electricity a 3D printer uses. Examining the power supply rating is one of the quickest methods. Only the absolute maximum is provided, so you are not given a precise number. Adding up the energy used by all electrical components results in a more accurate estimate.

It’s time to start printing now that you understand how to cut these costs! If you want to learn more about 3D printing, read our post on best 3D printer for miniatures.