One of the most intimidating aspects of this technology is that a single 3D printing job could take up to 12 hours or more, as anyone who has done any research on the subject is aware.

How much power does a 3D printer use is one of the questions about 3D printers that I get asked the most frequently from people who have never used one? Most people don’t know and are curious about them due to what they have heard, including many people who have worked with them.

Based on the test I did with a larger 3d printer, the average power consumption was 189.52 watts, or .018952 kilowatts, which means it would cost $0.023 to run the printer for an hour.

Read on as we delve a little deeper into the power usage of 3D printing.

Table of Contents

How To Calculate Power Consumption Of 3D Printer?

We’ve just seen the highest cost per hour of printing on an Epsilon W50; however, there are other factors that can affect how much ink a 3D printer uses.

- The printer model: There are other 3D printers that consume much more than those of BCN3D, reaching 1700W, so having a machine with low energy efficiency could double the electricity costs, at around 0.4 € per hour.

- The filament: Each material must be melted at a different temperature; for instance, PLA melts at 200°C and ABS at 240°C. As a result, printing PLA instead of ABS will use less energy.

How Much Power Does A 3D Printer Use?

An average 3D printer uses 70 watts of power with a heated bed of 60 degrees Celsius and a hotend of 205 degrees Celsius. This would require 0.7kWh, or about 9 cents, to print for 10 hours. The amount of electricity your 3D printer uses primarily depends on the size of your printer and the temperature of the heated bed and nozzle.

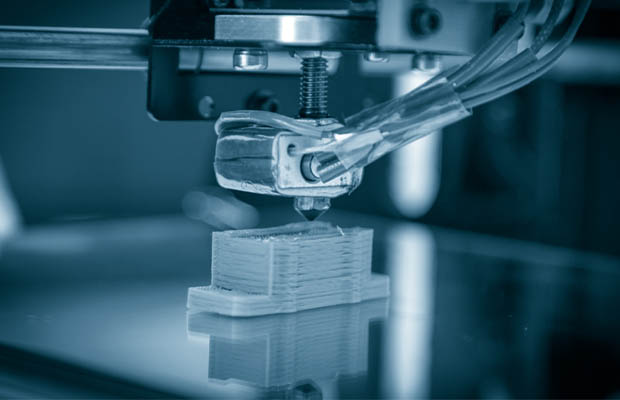

Components That Consume The Power On A 3d Printer

I wanted to discuss what is actually consuming the power before I explained how I arrived at the average power consumption. A 3D printer’s mechanical design is fairly straightforward, and there are only six different energy-consuming device types.

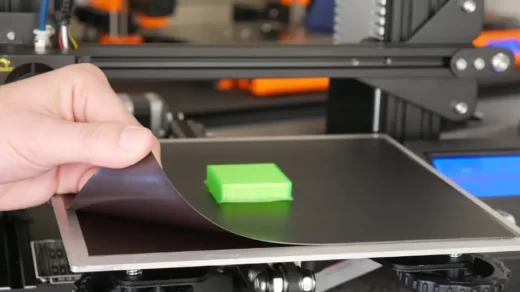

Build Plate

Today’s 3D printers have heated build plates for the most part. The same method used for the hotend is used to heat the build plate. It is equipped with a heating element that is attached to the bottom and heated to the temperature specified in the g-code file.

The heating element consumed a lot of energy when it was activated, but it was only used to heat the built plate to its initial temperature and to maintain it as needed. It’s crucial to coordinate the build plate’s temperature with the filament’s requirements.

Hotend

The filament is melted as it is forced through the extruder by the hotend. It is warmed to the print temperature specified in the g-code file by a heating element linked to a heat block.

Until it reaches the proper temperature and is turned off, that heating element consumes a lot of power, which is covered by the mainboard and power supply. After that, it is briefly turned back on to maintain the temperature. There is no power being used when it is off.

Main/Control Board

The mainboard, like the SKR Mini on Amazon, is essentially the 3D printer’s brain. The stepper motors’ wheels are turned, the print is tracked, and many other things are handled by it. Even though it’s the most important part of the print, it consumes very little energy and can even be powered by a USB.

To decrease power usage and noise while boosting performance, the mainboard can be upgraded. If your 3D printer supports it, the SKR Mini (on Amazon) would be a good choice. One of these is in my Ender 3 Pro, which is available on Amazon.

Display

You would use the display as the 3D printer’s control interface, and it consumes very little power. It is directly attached to the mainboard and can be as basic as a regular LCD screen or full color and touch-screen.

To operate the 3D printer without a screen, you would need to connect it to a computer or use a Raspberry Pi (available on Amazon) running OctoPrint.

Stepper Motors

A 3D printer has at least four stepper motors. They are in charge of feeding filament into the extruder and advancing the build plate along the X, Y, and Z axes. Since they are essential to the operation of the 3D printer, these motors typically consume only a few watts per unit.

Fans

A 3D printer typically has three or more fans, such as these fans from Amazon (not counting the power supply). One of the fans is used to cool the heat sink on the hotend to assist in controlling the nozzle temperature, another one is used to assist in cooling the filament as it is being inserted, and the final fan is used to maintain a stable temperature on the mainboard.

For each of these tasks, some printers employ multiple fans. The performance of the printer as a whole is significantly impacted by the fans, even though they are typically small and consume very little power.

A little less than a third of the average power consumption is used by the mainboard, display, stepper motors, and fans together. The heating elements provide the remaining consumption.

How To Lower Electricity Costs With A 3D Printer?

- Use a smaller 3D printer

- Use 3D printing materials that don’t require a heated bed or high nozzle temperatures (PLA)

- Implement 3D printer settings that make 3D prints quicker

- Change to a larger nozzle so your prints don’t last as long

- Make sure you are 3D printing in a fairly warm environment

Finding ways to speed up your 3D prints and eliminate the need for as much heating is the key to reducing power costs with your 3D printer.

Use a larger nozzle, use less infill, print less frequently, or print more items at once to speed up prints.

Focus on lowering the heat to save more power as heating elements consume the majority of electricity.

Typically, this isn’t a problem because the associated expenses aren’t particularly high. You’ll undoubtedly spend more money on the filament itself than you ever would on electricity.

Tips To Get Better Efficiency

There are some things you can do to improve your printer’s efficiency, but they might not have a big impact, so you’ll need to decide whether or not doing them makes sense to you.

Reduce Print Time

Cutting the print time as much as possible is another option you have to lower the power consumption. Simple: if the printer runs for a shorter period of time, it will consume less energy. Having said that, you still need to take care to print an object correctly and to consider its intended use. Because you’ll likely have to reprint it and use more power, you don’t want to make any changes below if they result in a print that isn’t functional.

Here are a few methods for cutting down on print time.

- Reduce infill

- Change infill pattern

- Reduce or remove supports

- Increase the layer height

- Reduce wall thickness

- Reduce or remove supports

- Only use a raft if absolutely necessary

- Increase print speed

Use An Enclosure

The amount of energy required by the heating elements to maintain the desired temperature will increase as the room temperature decreases. Running a 3D printer in an enclosure will help maintain a more constant temperature and reduce the amount of time that the heating elements are needed. This is particularly true in areas with a lot of breezes or where you can purchase a vent. The way it does this is by obstructing the external environmental factors that might affect the build plate and heating block’s temperature.

Some printers come with enclosures, but many popular models, like the Ender 3 and CR-10, which you can purchase from Amazon, don’t. If that’s the case with your printer, you can either purchase an enclosure that has already been built or build your own.

Print When Temperature Is Low

The heating elements must exert more effort to achieve and maintain higher temperatures. If you can print at a lower temperature, you’ll use less energy overall because the heating elements won’t need to be on as frequently. In many instances, you can get away with lowering the build plate and hotend temperatures by 10 and 5 degrees, respectively, without the print being negatively impacted.

However, lowering the temperature is not always an option, so you must print at a temperature that complies with the filament’s specifications. I advise printing a temperature tower to determine the ideal printing temperature for the filament being used.

Obtain A More Efficient Power Supply

The majority of 3D printers ship with inefficient power supplies, so replacing them with one that is more effective will lower the overall power consumption. To notice much of a difference, you would really need to switch to a power supply rated in platinum. If you want to save money, avoid making this change. You probably won’t make back the cost of the power supply within the lifespan of the 3D printer unless it runs nonstop.

Having said that, not many power supplies will function with a 3D printer out of the box; you would need to make some adjustments to make them work. If you are not confident in your ability to make that kind of change, I would not advise doing this. You risk ruining the mainboard if something is done incorrectly.

Get A Battery Backup

While this won’t directly lower power usage, it can lower the number of unsuccessful prints, which will lower the power used for that print. This is particularly true if you reside in an area that frequently experiences power outages or if you own a 3D printer that doesn’t automatically restart when the power goes out.

The wattage specified on the power supply of the 3D printer must be handled by the battery backup. It is 360 watts in this example. You should also think about how frequently the power goes out and how long you want the printer to run when the power is out.

The battery backup that I suggest is available on Amazon.com. At a reasonable cost, it offers a ton of coverage. Its omission of the remaining runtime is the only aspect of it that I dislike. If you want that feature, the cost starts to rise sharply.