When it comes to getting the best results from 3D printing, the printing bed is crucial. All things considered, it acts as the model’s support surface. As a result, you must pay special attention to this printer component.

Regardless of the 3D print bed surface, you select, regular cleaning and maintenance are crucial to extending the life of the surface and ensuring strong first-layer adhesion, which will help prevent failed prints.

This article will give you a thorough explanation of the various options so that you will know how to clean the print bed effectively. You’ll find this useful, especially as a beginner.

Table of Contents

Why Should 3D Printing Bed Be Cleaned?

The print bed of a printer may develop deposits if it is used frequently. If you heat it, this is particularly true. The filament may adhere to the surface if the temperature is sufficiently high.

It follows that any residue is left behind even after the model is taken out. The results of subsequent prints may suffer as a result, which can negatively affect adhesion.

In some circumstances, using adhesive to secure the model to the print bed is even necessary. Because of the residual adhesive left over from the 3D printing process, the model won’t slide around during the duration of the print. In a perfect world, you would get rid of these right away.

As a result, you should check the print bed after each device activity. If it’s dirty, clean it right away. In addition, the printer will look brand-new and continue to function as intended.

Benefits Of Cleaning 3D Printing Bed

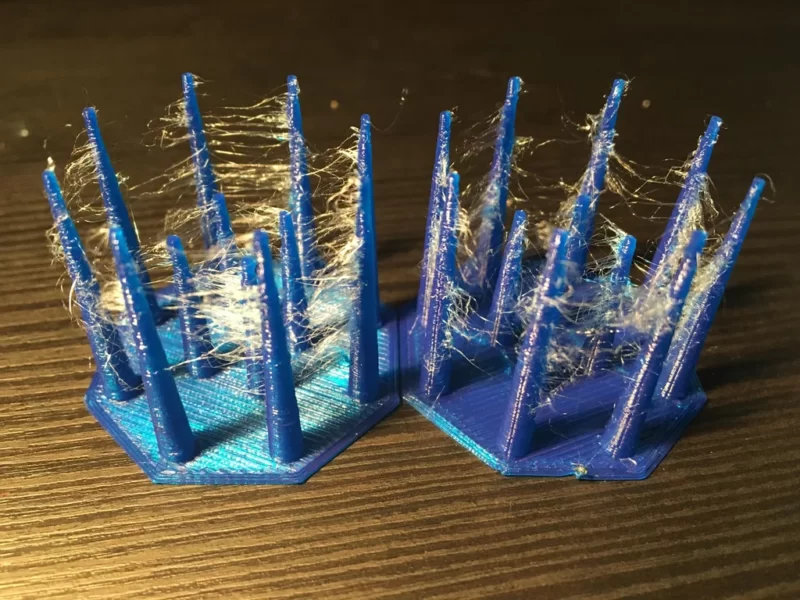

The best results can only be obtained with a clean 3D printer bed. Layer adhesion problems that occur frequently on dirty beds degrade the caliber of your prints.

You can avoid spending a few extra dollars on somewhat pricey replacements by maintaining the 3D printing bed in a usable condition and extending its useful life.

The first layer’s quality and its adherence to the build plate are two major printing problems.

Your models will print flawlessly and correctly on a clean 3D printer bed. As recommended care for printing beds varies depending on model and material, keep in mind to follow it.

Supplies Used When Cleaning 3D Printing Bed

Window Cleaner

Window cleaner can be used to clean a glass build surface

In addition to other grease-dissolving agents, spray-bottle window cleaners frequently include alcohol, such as ethanol or isopropanol. Although less additive-containing products are preferable for cleaning print beds, they may also contain additives like perfumes.

Window cleaning sprays are designed specifically for cleaning glass, so they can be effective at cleaning glass print beds and surfaces.

Soap

Cleaning various print surfaces with regular dish soap and warm water is a simple and affordable solution. The best products are those with few additives and no scent.

Isopropyl Alcohol

Antiseptics, detergents, and disinfectants frequently contain the colorless chemical compound isopropyl alcohol (IPA). It sometimes goes by the name “rubbing alcohol” because it was once used as a topical massage preparation.

IPA, which contains between 70 and 90 percent alcohol, can be used by FDM users to clean print surfaces like PEI and glass. Although the chemical won’t likely harm these surfaces, it is potent enough to remove grease and residue.

Acetone

Acetone, which can be found in items like paint thinner and nail polish remover, is another substance that is used to clean the build surfaces and beds of 3D printers. Since the solvent can dissolve the plastic (though it won’t cut through PLA), it is also used as a smoothing agent for ABS prints.

Acetone works well to remove some types of plastic filament residue and dirt from glass beds. A plastic surface can be harmed if used too frequently, but it can also be used to clean PEI and other surfaces.

Equipment

A few pieces of equipment are required in addition to chemical agents to clean a printing surface. The following items should be accessible:

- Scraper: A flat-blade scraper is used to remove residue without damaging the print bed or building surface

- Sandpaper: More abrasive than a scraper or cloth, sandpaper can help maintain an even surface

- Cloth: A soft microfiber cloth can be used to apply various substances to the print bed or build surface

- Paper towels: Paper towels are suitable for applying mild cleaning agents like soapy water and window cleaner

Read More: How to Level a 3D Printer Bed?

Tips To Clean 3D Printing Bed

Glass

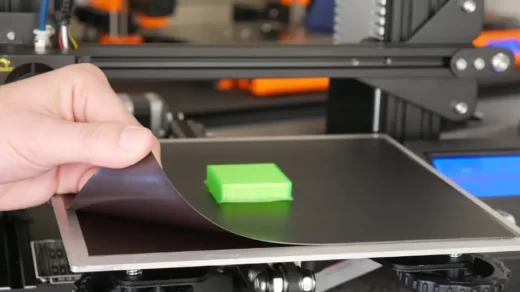

Due to its ability to disperse heat evenly and ease of maintenance, glass is one of the most widely used and effective building materials. A removable glass sheet (typically borosilicate glass) is sometimes attached to a metal print bed by some users, whereas some printers have glass print beds.

Glass offers a flat printing surface, but because of its smoothness, good first-layer adhesion may not be possible. In order to prepare the glass surface for printing, users frequently apply glue or another adhesive. Because of the buildup of residue that results from this, it is important to clean the area between prints.

Cleaning glass 3D printing platforms:

- To avoid the cleaning solution getting into the mechanical components of the printer, if at all possible, remove the glass plate from the print bed.

- With a dry scraper and firm, even pressure, remove any substantial pieces of glue or filament residue.

- About once a month or as needed (but only if the surface can be removed from the printer), clean grease and another residue from the glass using a cleaning cloth dipped in warm, soapy water. You could also use window cleaner.

- Before each print, wipe the surface with IPA while wearing safety gloves.

- Wherever possible, try to keep your hands off the glass to prevent fingerprints.

Pei

A chemically stable thermoplastic known as polyetherimide (PEI) is used as a printing surface because of its favorable material properties, including heat resistance. PEI sheets that are inexpensive can be fastened to a build plate and endure numerous print cycles.

Its superior adhesion, especially with materials like ABS, is one benefit of using a PEI sheet over the glass. Normal practices avoid using additional adhesives like glue on the surface, which lessens residue buildup. But maintaining good adhesion necessitates routine cleaning.

How to clean PEI 3D printing beds:

- In order to prevent the cleaning solution from getting inside the mechanical components of the printer, if at all possible, remove the PEI surface from the print bed.

- To get rid of gunk and residue, soak a dry cloth in IPA and wipe the PEI bed surface. Each print should be followed by this process. As an alternative, use warm water and dish soap.

- To further clean and smooth the plastic surface, apply acetone with a cloth once every month.

- If the surface is scratched, smooth it out with fine-grit sandpaper. Replace the PEI sheet if the flaws are too severe to be repaired.

- Anywhere you can, try to keep your hands off the PEI.

Adhesive Tape

The typical build surfaces for FDM 3D printers without heated beds are blue painter’s tape, a type of masking tape, and NASA-developed Kapton tape.[2] (The tape’s adhesive side’s glue could be melted by a heated surface.) A taped print bed may have an unprofessional appearance, but it still functions well and is simple to change.

Using adhesive tape has the obvious drawback of having tiny seams between each strip, which can leave a line on the base of a print. The use of thicker tape, however, can somewhat mitigate this issue. Additionally, since tape cannot be cleaned with solvents or other wet cleaning agents, it is more difficult to clean tape than solid surfaces like glass.

Blue painter’s tape should be scraped clean and replaced when worn

How to clean a 3D printing bed using adhesive tape:

- To eliminate residue and lingering filament, use a dry scraper.

- Replace any tape that has been damaged. In order to prevent problems with subsequent prints, try to keep the surface level whenever you can.

- Wherever possible, try to keep your hands off the tape to prevent fingerprints.

- When the tape bed is clearly worn, torn, or uneven, replace the entire tape bed. Before putting on the new layer, clean the bed underneath with IPA or acetone to get rid of any glue stains.

Buildtak

BuildTak is an inexpensive, heat-resistant adhesive sheet that is simple to use, clean, and replace. It is one of the most well-known brand printing surfaces. Users speculate that even though its composition is unknown, it might be made of glass and PEI.

BuildTak 3D printing bed cleaning instructions:

- To remove grime and residue from the BuildTak surface, IPA-soak a dry cloth. Between prints, repeat this process.

- If the IPA is ineffective, try using warm water.[3]

- Where possible, keep your hands off the BuildTak surface to prevent fingerprints.

- When the BuildTak surface becomes worn and the parts no longer adhere to the bed, replace it.

What Should Be Avoided During Cleaning?

You must avoid using abrasive agents if you want to guarantee that all filaments adhere well over time. Your device’s print bed will be destroyed by this. The filaments will lose their ability to cling to the surface if you leave scratches on it.

A sponge with a rough surface should also be avoided because of this. A scratched print bed can also happen as a result of this.

Additionally, use acetone with caution. Due to its overly aggressive effect, it is inappropriate for a coated bed.

Remember to ventilate the space after you’ve cleaned the print bed. This will guarantee that poisonous fumes leave the space.

How Often To Clean 3D Printing Bed?

Ideally, the print bed should undergo routine basic cleaning. This makes sure that filament leftovers won’t stick to it indefinitely. After each prolonged printing process, you should carefully inspect the component. Look for any stains, adhesive left over, and deposits of course.

In the event that the print bed is obviously dirty, you must always clean it. The earliest you can clean it up after discovering the contamination is. Long-term, this will keep the print bed tidy.

It is also worthwhile to look at the component if you haven’t used the 3D printer in a while. Over time, dust can build up on it. Although this is not a serious flaw, the particles may cause the model to adhere poorly. Typically, wiping the print bed with a damp cloth will suffice in this situation. You can prevent the use of more aggressive cleaning agents by performing a light cleaning at regular intervals.

The manufacturer should be contacted if you are still unsure of how to clean the 3D printer. They can offer you advice on how to prevent errors and, consequently, damage.

The Bottom Line

3D prints can fail for a variety of reasons, and one of the most common is a part detaching from the print bed mid-print. Therefore, proper bed adhesion is essential for successful printing.

Although cleaning a 3D printer’s surface may seem easy, it can actually be more difficult than it appears.

Although there are many ways to keep your parts stuck, one of the simplest is to keep the print bed clean. In addition to enhancing part adhesion, routine bed cleaning may also improve the appearance of your prints.